█████╗ ██████╗ ██████╗██╗ ██╗██╗██╗ ██╗███████╗██████╗ ██╔══██╗██╔══██╗██╔════╝██║ ██║██║██║ ██║██╔════╝██╔══██╗ ███████║██████╔╝██║ ███████║██║██║ ██║█████╗ ██║ ██║ ██╔══██║██╔══██╗██║ ██╔══██║██║╚██╗ ██╔╝██╔══╝ ██║ ██║ ██║ ██║██║ ██║╚██████╗██║ ██║██║ ╚████╔╝ ███████╗██████╔╝ ╚═╝ ╚═╝╚═╝ ╚═╝ ╚═════╝╚═╝ ╚═╝╚═╝ ╚═══╝ ╚══════╝╚═════╝

|

Important

|

This repository has been archived. This means that there will be no new development nor security updates and pull requests will not be accepted. The builder system was taken down. |

The development continues in two separate repositories:

-

Machinekit-HAL: https://github.com/machinekit/machinekit-hal

-

Machinekit-CNC: https://github.com/machinekit/machinekit-cnc

Original, frozen .deb packages for Machinekit will be available in deb.machinekit.io repository for the foreseeable future.

THE AUTHORS OF THIS LIBRARY ACCEPT ABSOLUTELY NO LIABILITY FOR ANY HARM OR LOSS RESULTING FROM ITS USE. IT IS EXTREMELY UNWISE TO RELY ON SOFTWARE ALONE FOR SAFETY. Any machinery capable of harming persons must have provisions for completely removing power from all motors, etc, before persons enter any danger area. All machinery must be designed to comply with local and national safety codes, and the authors of this software can not, and do not, take any responsibility for such compliance.

Machinekit is a platform for machine control applications.

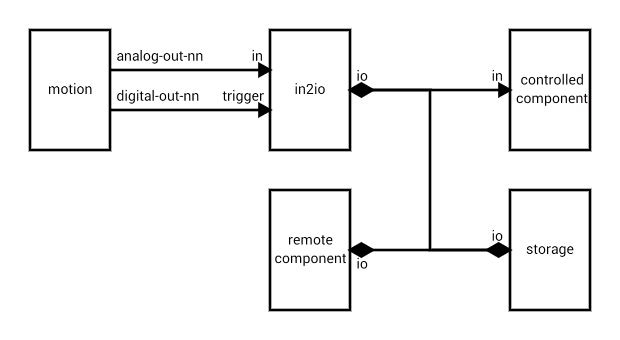

Machinekit is portable across a wide range of hardware platforms and real-time environments, and delivers excellent performance at low cost. It is based on the HAL component architecture, an intuitive and easy to use circuit model that includes over 150 building blocks for digital logic, motion, control loops, signal processing, and hardware drivers. Machinekit supports local and networked UI options, including ubiquitous platforms like phones or tablets.

The easiest way to get up-and-running is to install Debian Stretch and get the binary packages.

Please go to www.machinekit.io for this and all other information, including documentation.

The open-source Machinekit project forked from the open-source LinuxCNC project (http://www.linuxcnc.org) in 2014. At the present time, identifiers such as 'linuxcnc' and 'emc' (the antecedent of linuxcnc) still occur in various places. These occurrences are diminishing with time as the Machinekit codebase and Machinekit documentation evolve.